Eco-Friendly Layout: How Sustainable Warehouses are changing the Logistics World

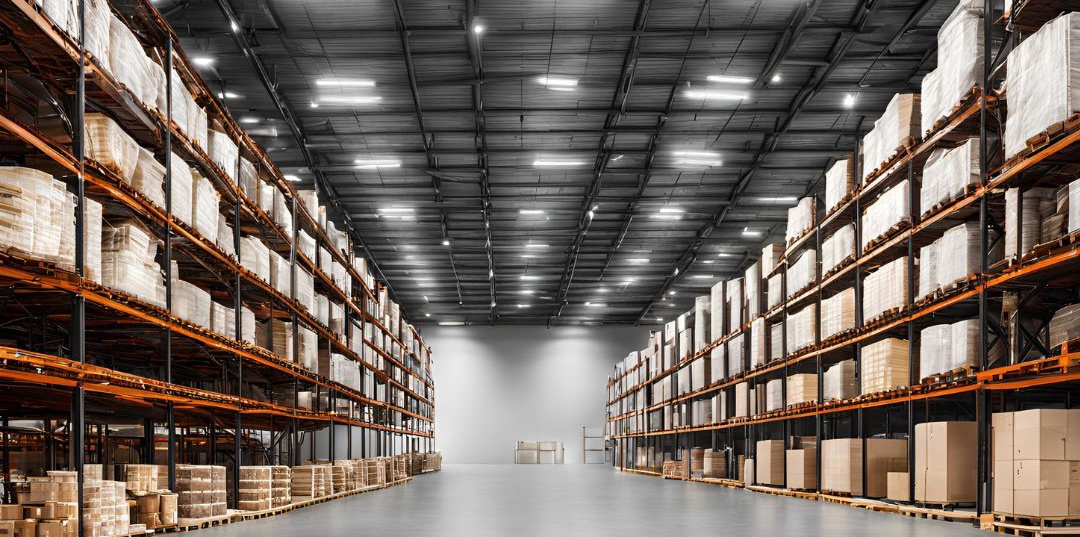

In recent years, sustainability has become a central theme for many companies, and warehouses, the backbone of modern logistics, are at the forefront of this transformation. Optimizing warehouses and their layout to reduce environmental impact is not just an ethical choice but also an opportunity for operational improvement and cost reduction. But how can a warehouse become sustainable? Let’s explore the main solutions together.

Sustainability in Warehouses: why Is it important?

Warehouses are facilities that require enormous amounts of energy to operate, mainly for lighting, climate control, and handling equipment. Moreover, a warehouse's layout can directly influence the efficiency of operational flows, with significant impacts on fuel, energy, and material consumption.

Implementing sustainable practices within warehouses not only reduces CO2 emissions but also improves operational efficiency, reduces waste, and creates healthier working environments. The ultimate goal is to make the warehouse a key element of a greener and more responsible supply chain.

Solutions for sustainable warehouses

To transform warehouses into more sustainable spaces, companies are adopting various strategies. Here are some of the most effective solutions.

1. Energy efficiency and use of renewable energy

One of the most immediate ways to improve a warehouse’s sustainability is to reduce energy consumption by adopting more efficient systems and using renewable energy sources.

LED Lighting:

Replacing traditional lights with high-efficiency LED lighting is a simple yet highly effective first step. Automatic lighting systems that turn on and off based on personnel presence or natural light can further reduce consumption.

Solar Panels and Other Renewable Sources:

Installing solar panels on warehouse roofs can reduce dependence on fossil energy sources and cut energy costs in the long term. In some cases, warehouses can become energy self-sufficient.

Smart Climate Control Systems:

Efficient climate control management can help reduce energy use in warehouses while improving worker comfort. Natural ventilation systems, combined with the use of eco-friendly insulating materials, can help maintain a stable temperature without excessive energy consumption.

2. Layout Optimization

The warehouse layout plays a fundamental role in sustainability. An efficient space organization reduces travel times and the use of handling equipment, thereby decreasing energy consumption and environmental impact.

Flexible and Optimized layouts:

Designing a layout that minimizes the distance between storage areas and loading/unloading zones helps reduce the use of internal vehicles such as forklifts and pallet trucks. A more efficient arrangement allows for reduced handling time, saving fuel and energy.

Vertical storage:

Utilizing the height of the warehouse for vertical storage optimizes space, reducing the need to expand the physical footprint of the warehouse. This approach reduces the consumption of materials and the energy requirement for constructing new storage areas.

Sustainable automation:

Automation can be a crucial lever for improving warehouse sustainability. The use of robots and automated systems powered by renewable energy reduces the need for manual handling and can be designed to optimize energy consumption.

3. Eco-Friendly materials and packaging

Warehouses handle large amounts of packaging materials, often made of plastic or other difficult-to-recycle substances. Adopting sustainable packaging solutions can reduce the warehouse's overall environmental impact.

Recycled and Recyclable materials:

Using recyclable packaging and eco-friendly filling materials, such as recycled cardboard or biodegradable polymers, reduces the use of single-use plastic and helps promote a sustainable lifecycle for goods.

Reducing packaging waste:

Implementing custom-fit packaging solutions reduces the amount of materials used and the space occupied. Additionally, reducing the volume of packaging optimizes the use of space in trucks, decreasing the number of trips needed to transport goods.

4. Waste Management

Efficient waste management is crucial for warehouse sustainability. Implementing recycling and material reuse practices within the warehouse can help reduce waste and improve efficiency.

Waste sorting:

Warehouses can implement waste sorting programs to ensure that materials like paper, plastic, and metal are disposed of properly. This reduces the amount of waste sent to landfills.

Circular economy:

Integrating circular economy practices can help warehouses reuse materials that would otherwise be discarded. For example, used packaging or damaged pallets can be repaired and put back into circulation, reducing the need to produce new materials.

The Warehouse of the future is Green

Sustainable warehouses represent the future of logistics. By adopting energy-efficient solutions, smart layouts, and eco-friendly materials, these spaces can become critical points in a green supply chain. Companies that choose to invest in sustainable practices not only reduce their environmental impact but also optimize their processes and build a positive corporate image, preparing for a more sustainable future.